©Dinu Kennedy 2025

©Dinu Kennedy 2025

©Dinu Kennedy 2025

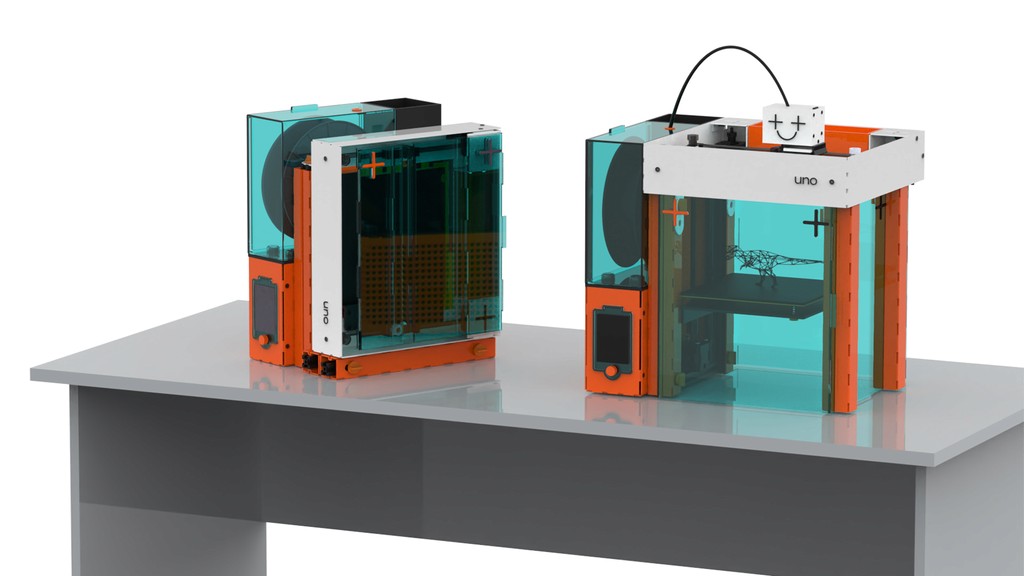

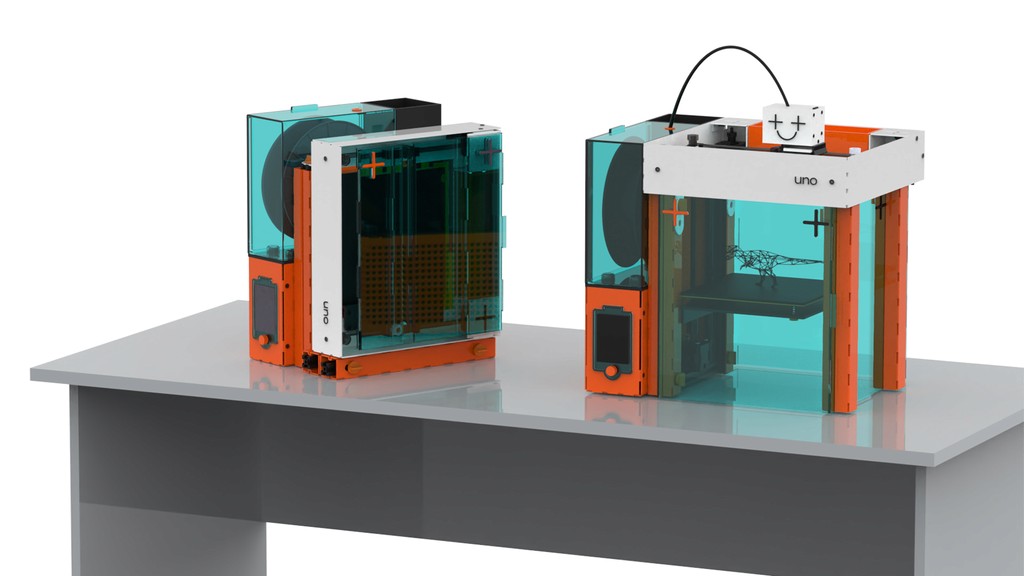

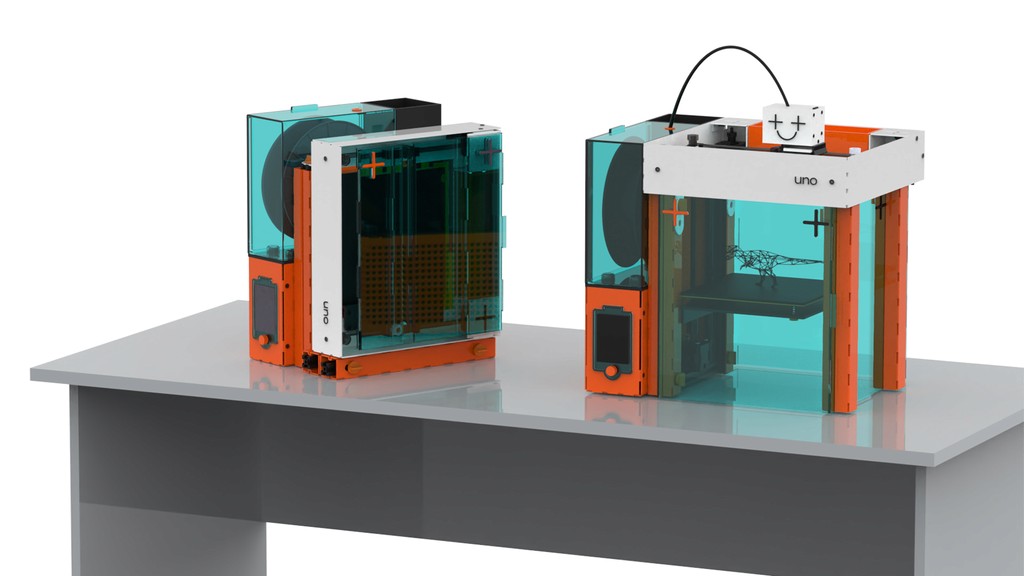

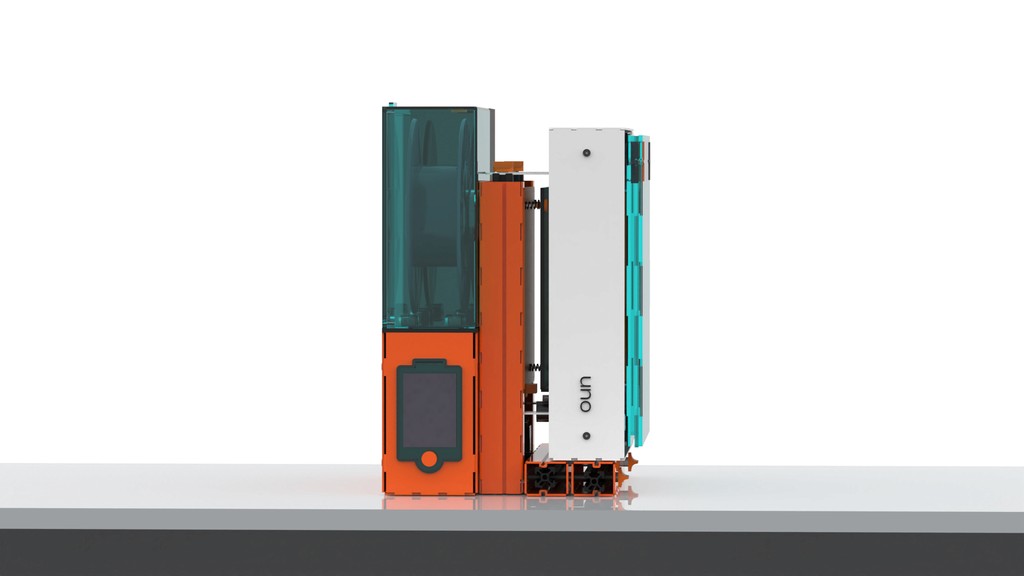

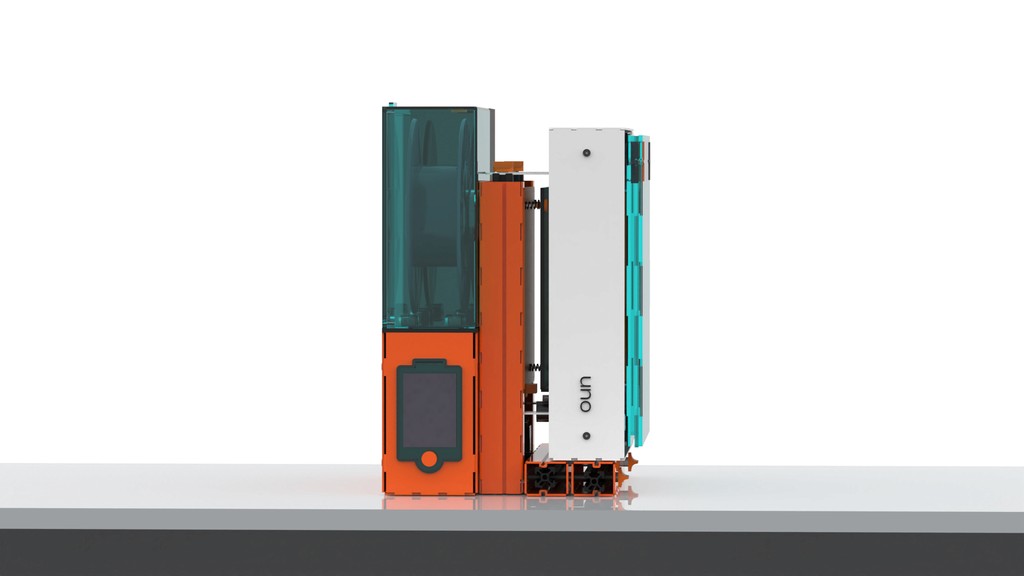

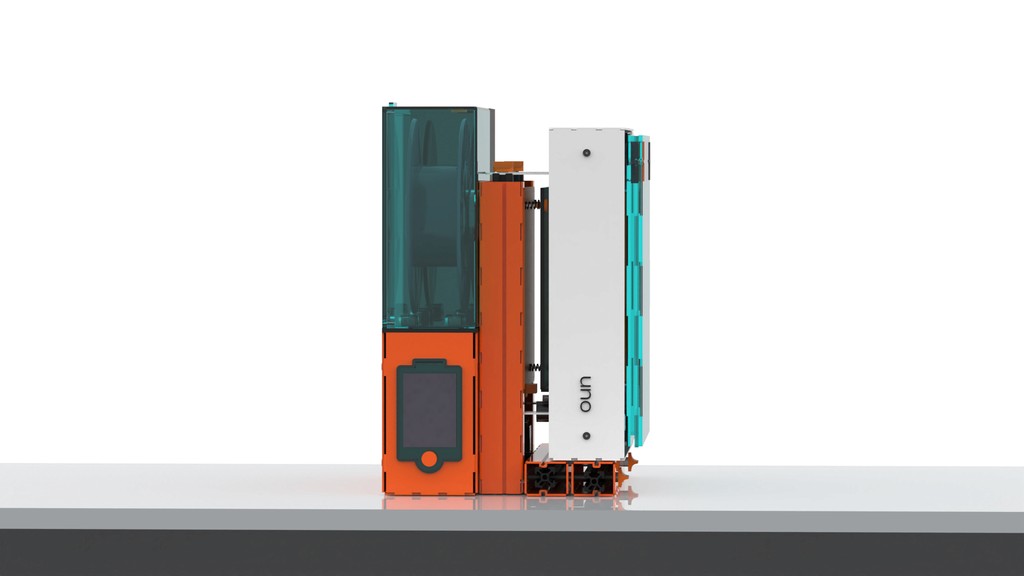

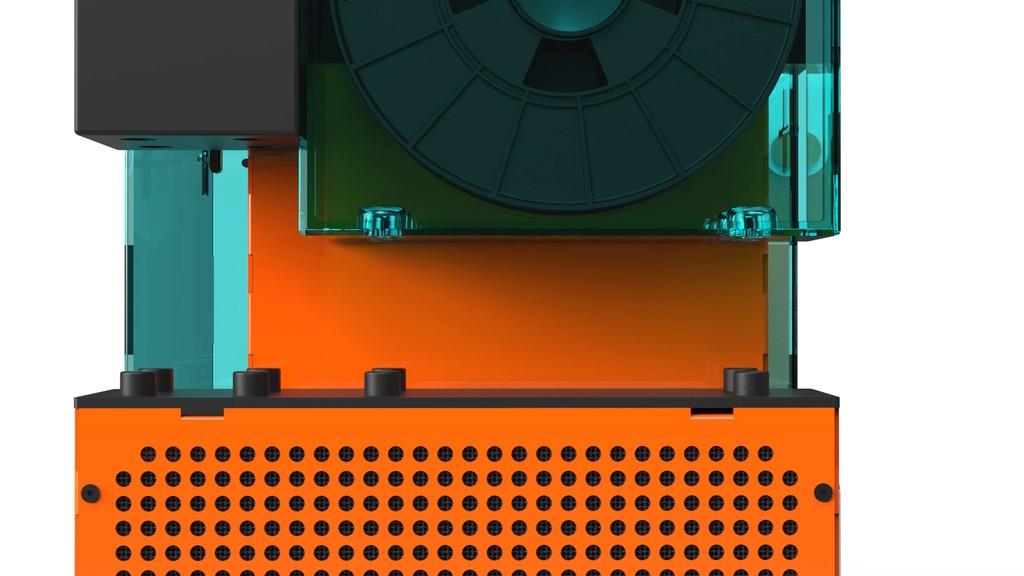

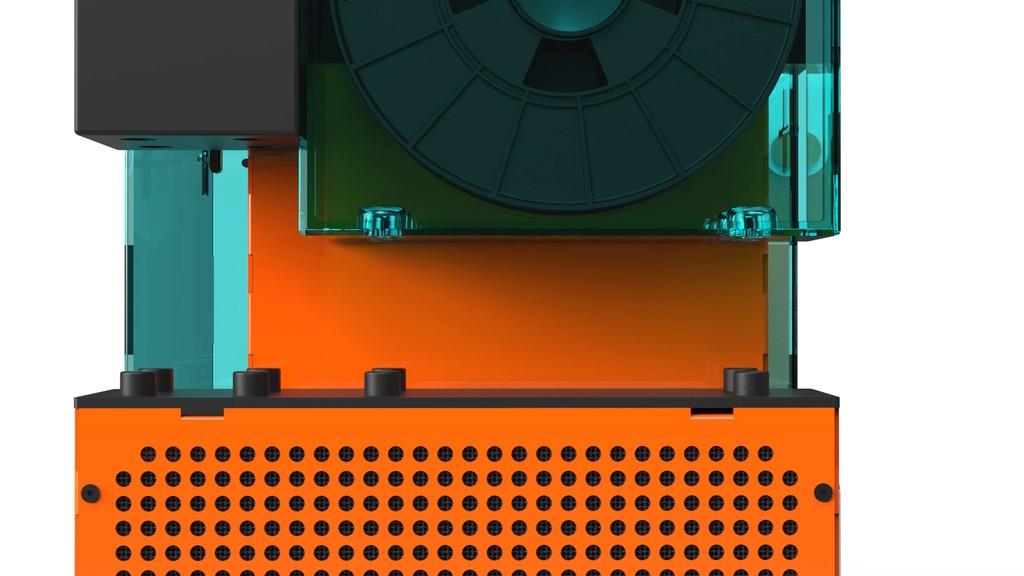

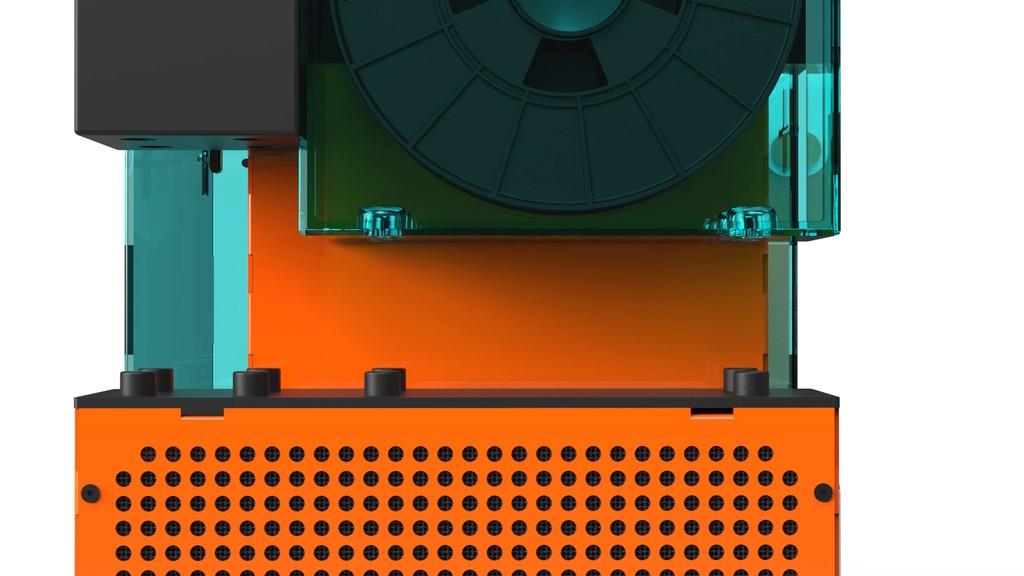

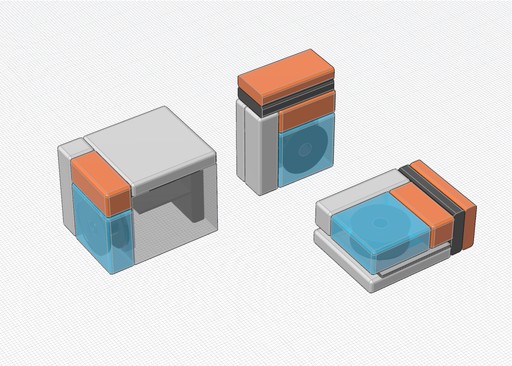

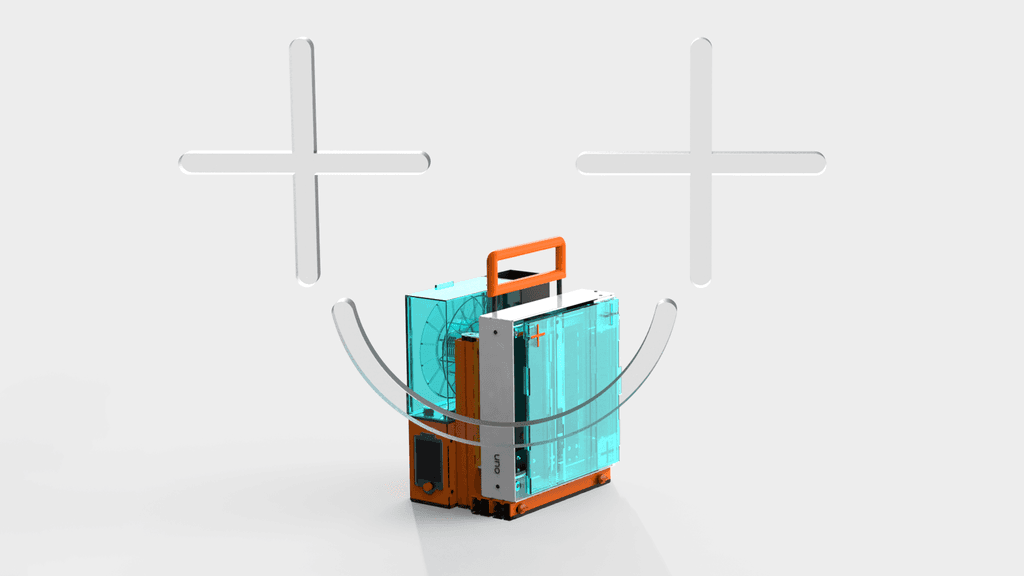

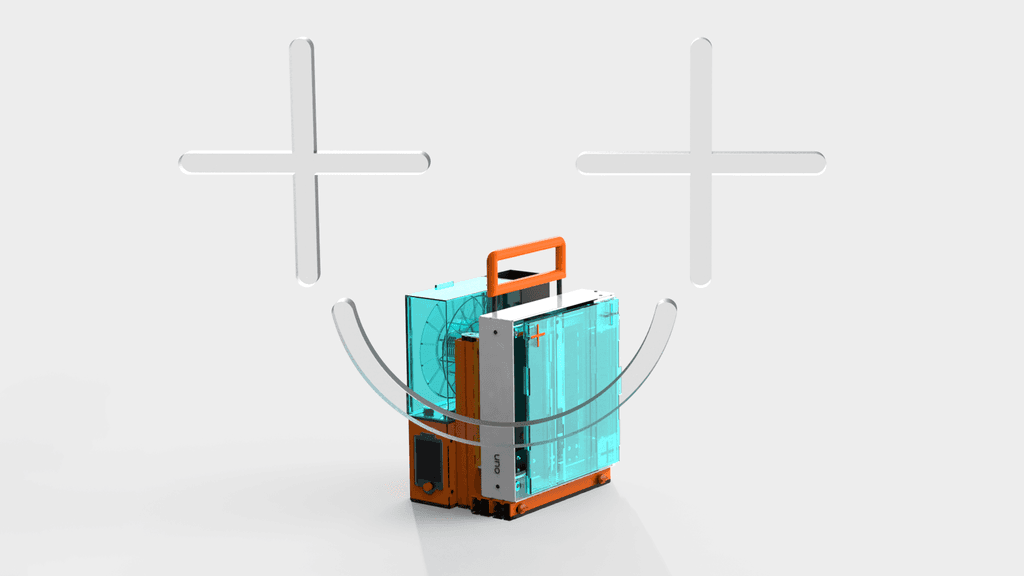

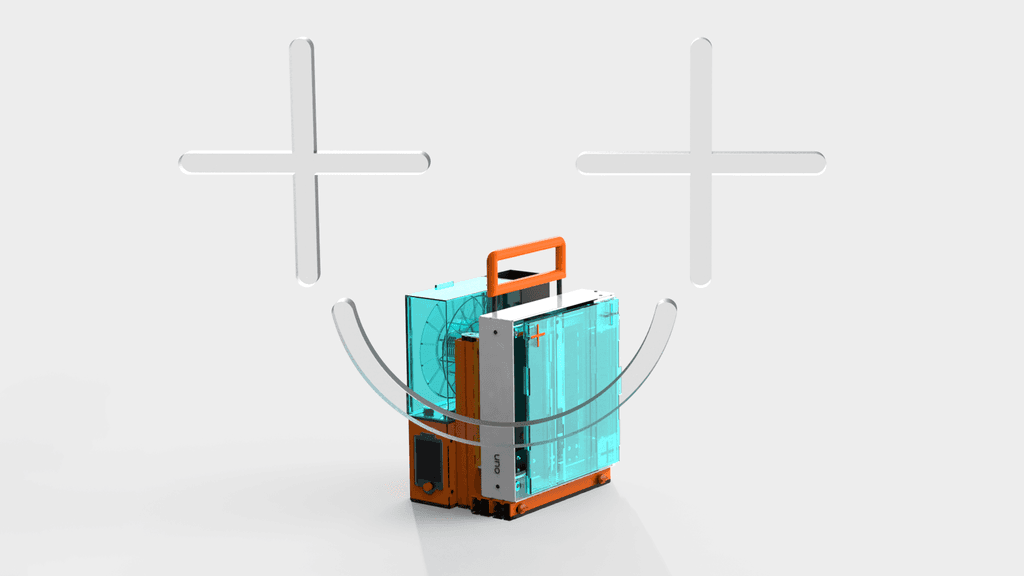

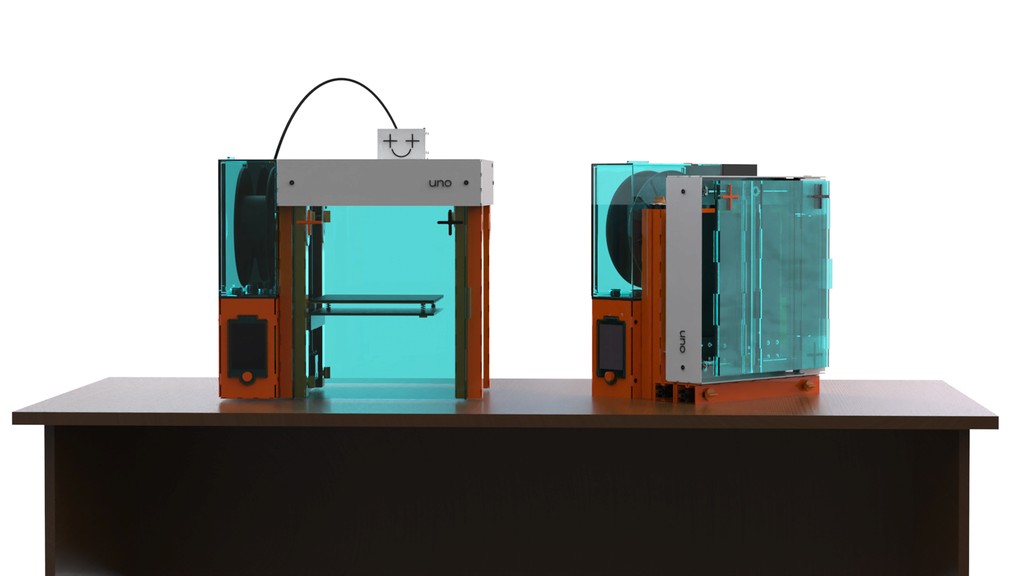

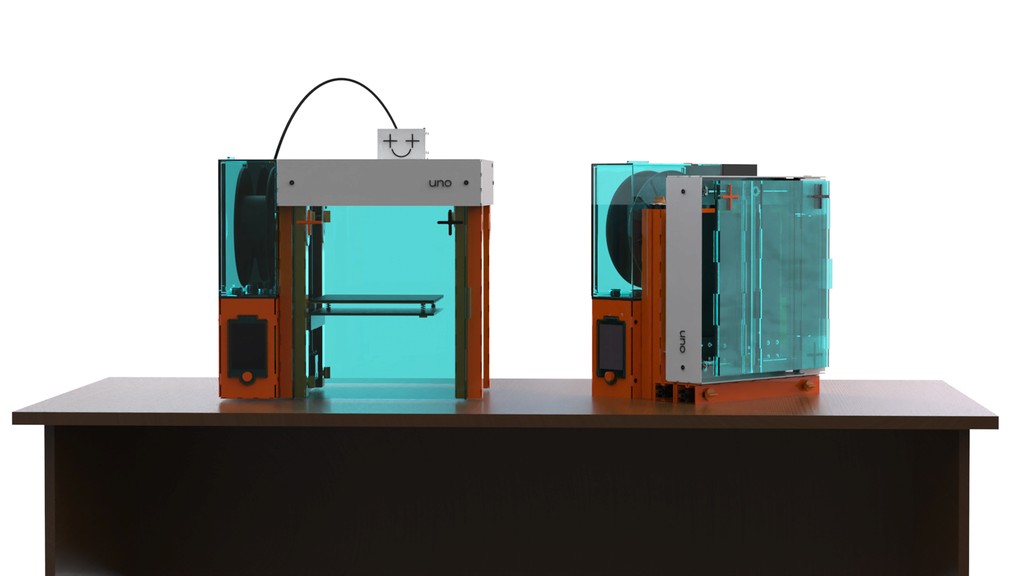

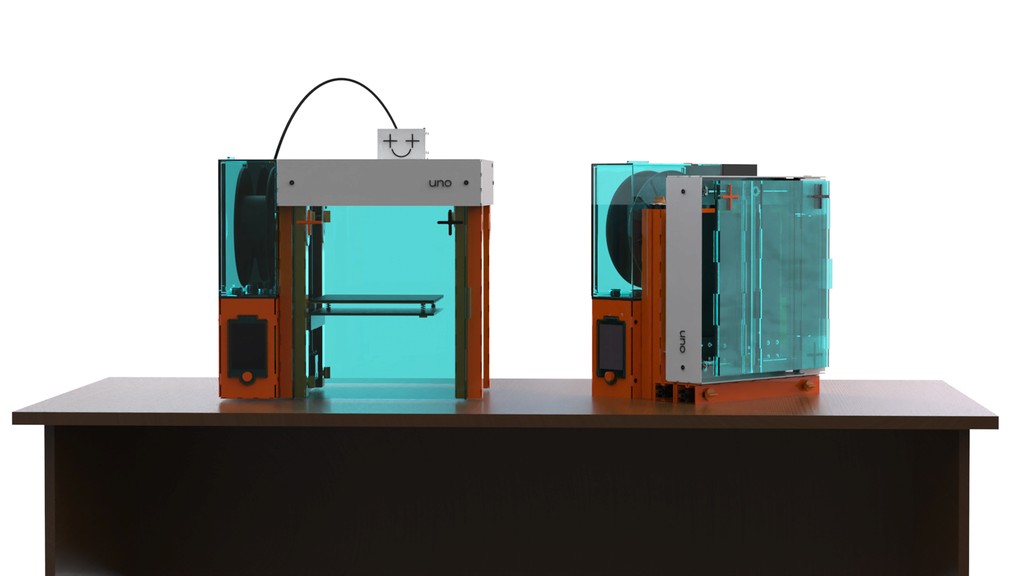

Stack UNO is a modular, collapsible 3D printer designed for hobbyist makers. It simplifies the printing process, making it more accessible while retaining the core components of a standard FDM printer kit. This ensures easy repairability and upgradability, keeping the design both functional and future-proof.

Stack UNO is a modular, collapsible 3D printer designed for hobbyist makers. It simplifies the printing process, making it more accessible while retaining the core components of a standard FDM printer kit. This ensures easy repairability and upgradability, keeping the design both functional and future-proof.

Industrial design

Industrial design

Can a 3d printer

kitmade as fun

as Lego?

Can a 3d printer

kitmade as fun

as Lego?

Can a 3d printer

kitmade as fun

as Lego?

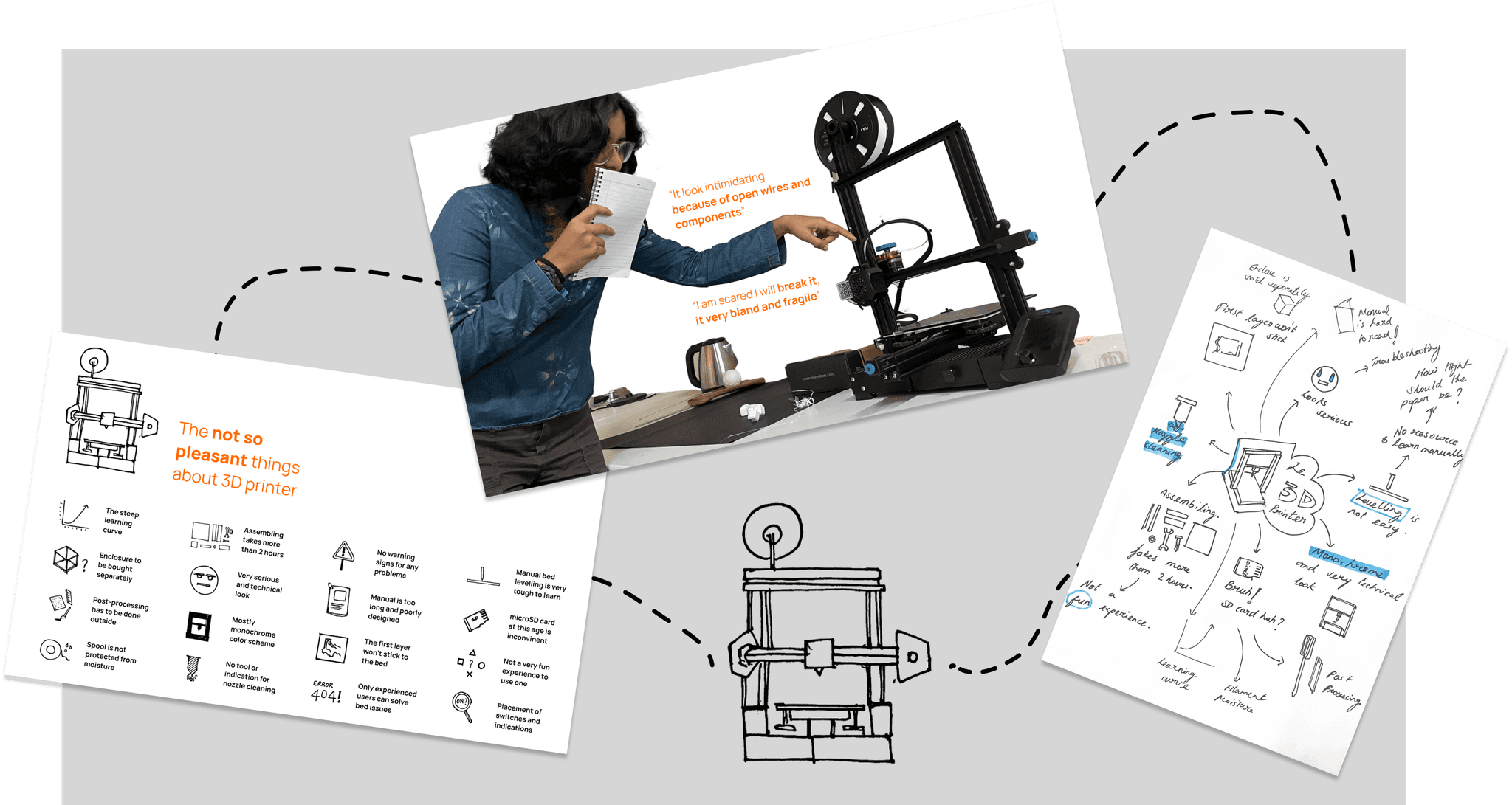

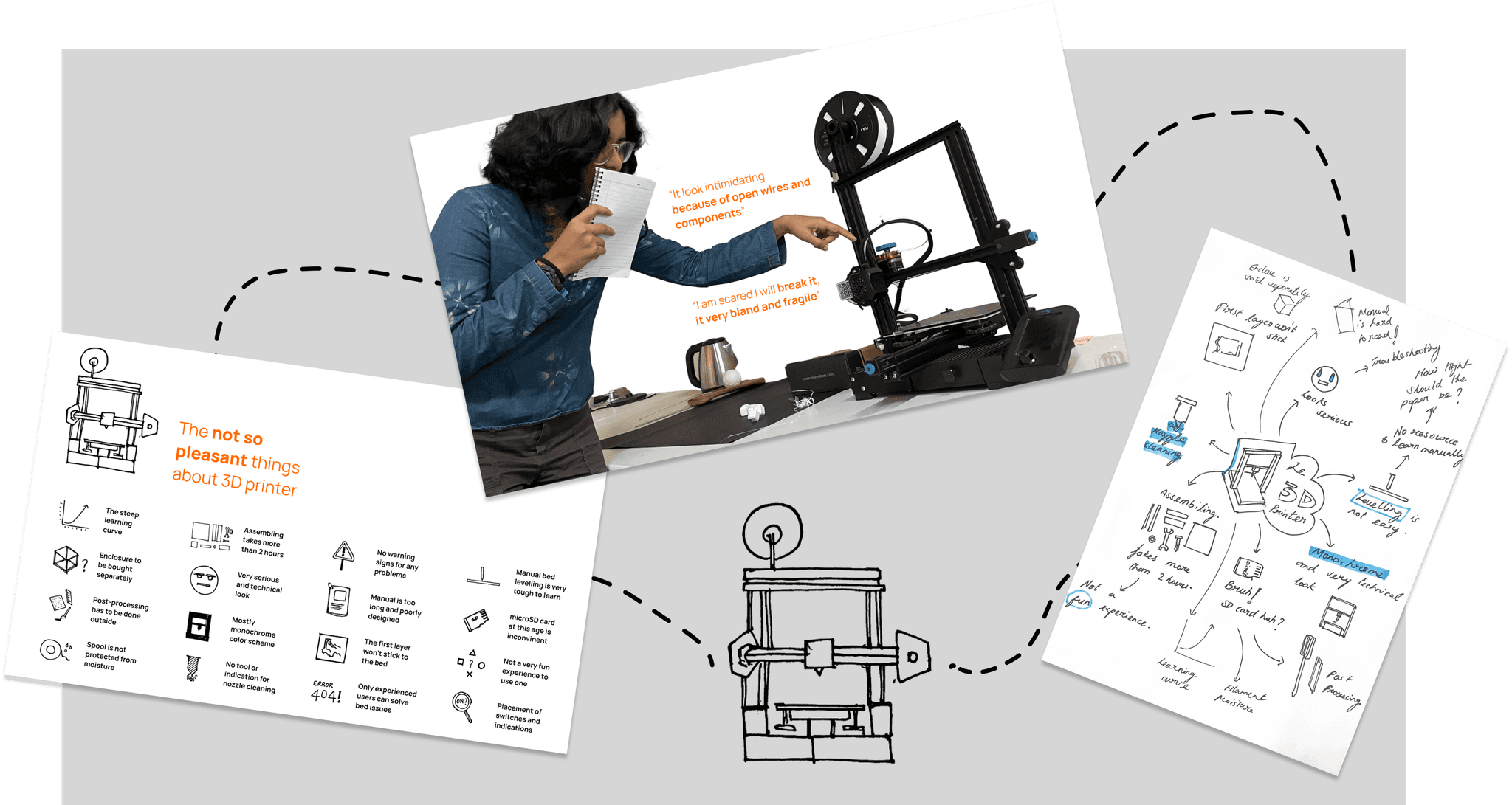

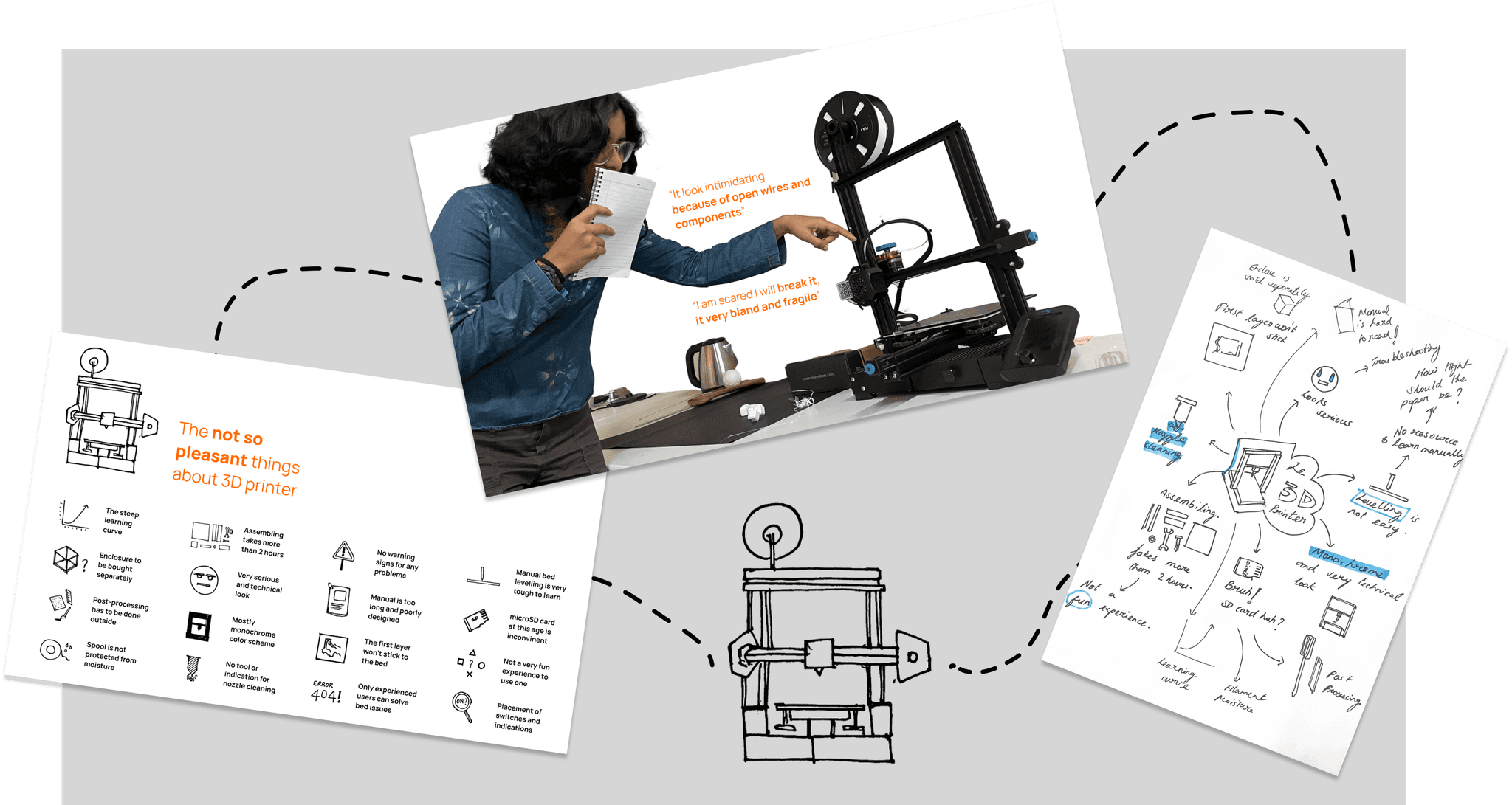

During my user research, I discovered that even enthusiastic 3D printing users often felt intimidated by the machine's appearance. While the primary goal of a 3D printer is to deliver an enjoyable experience, its design rarely reflects that. This insight inspired me to create a product that is both functional and approachable, making the interaction fun and easy.

During my user research, I discovered that even enthusiastic 3D printing users often felt intimidated by the machine's appearance. While the primary goal of a 3D printer is to deliver an enjoyable experience, its design rarely reflects that. This insight inspired me to create a product that is both functional and approachable, making the interaction fun and easy.

Assemble in just

minutes

Assemble in just

minutes

Assemble in just

minutes

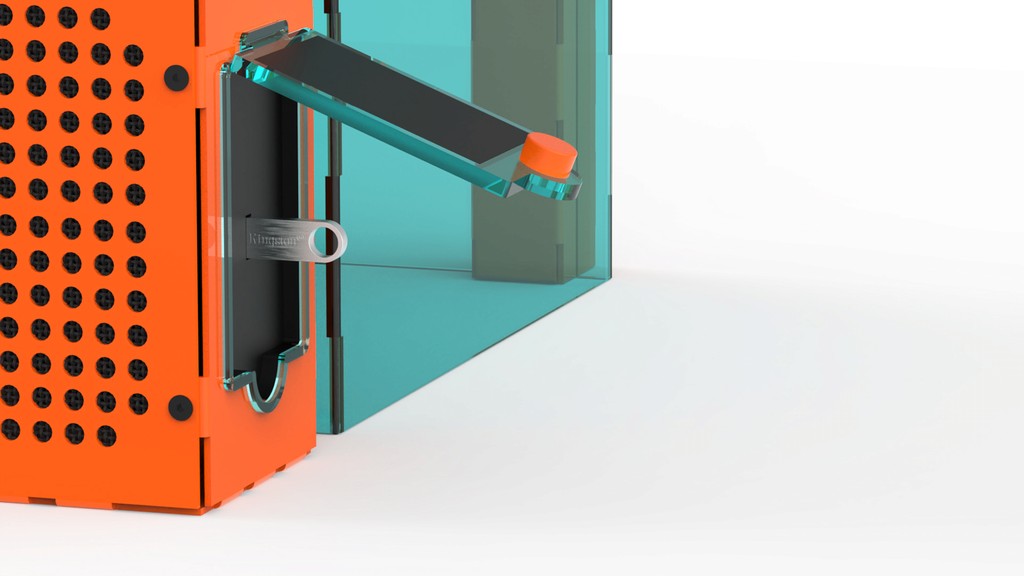

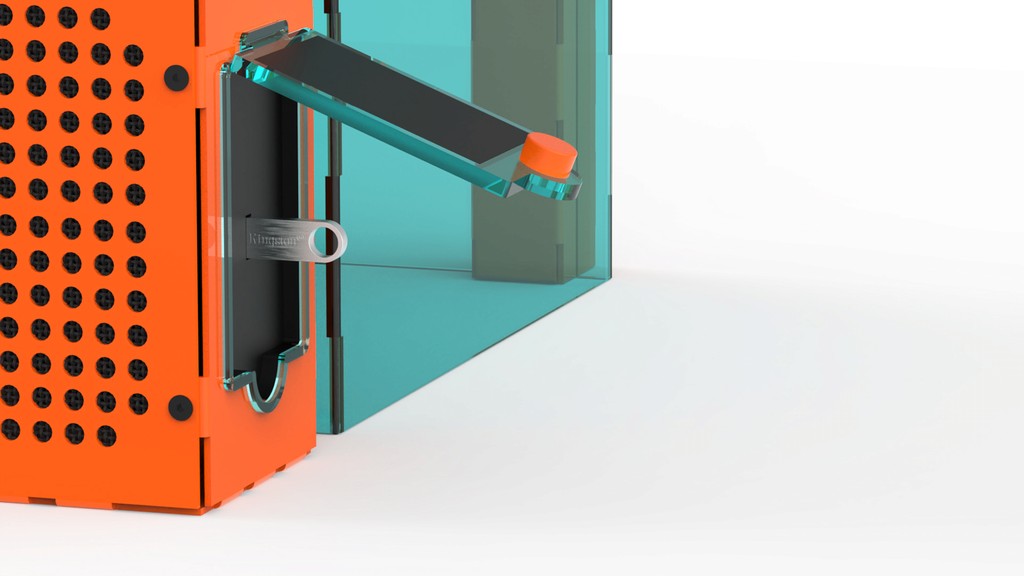

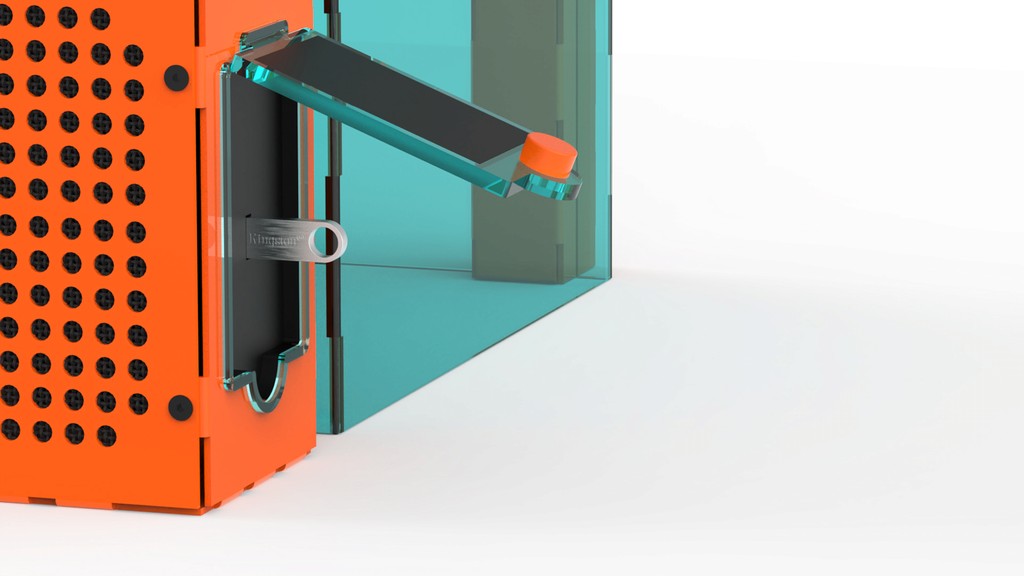

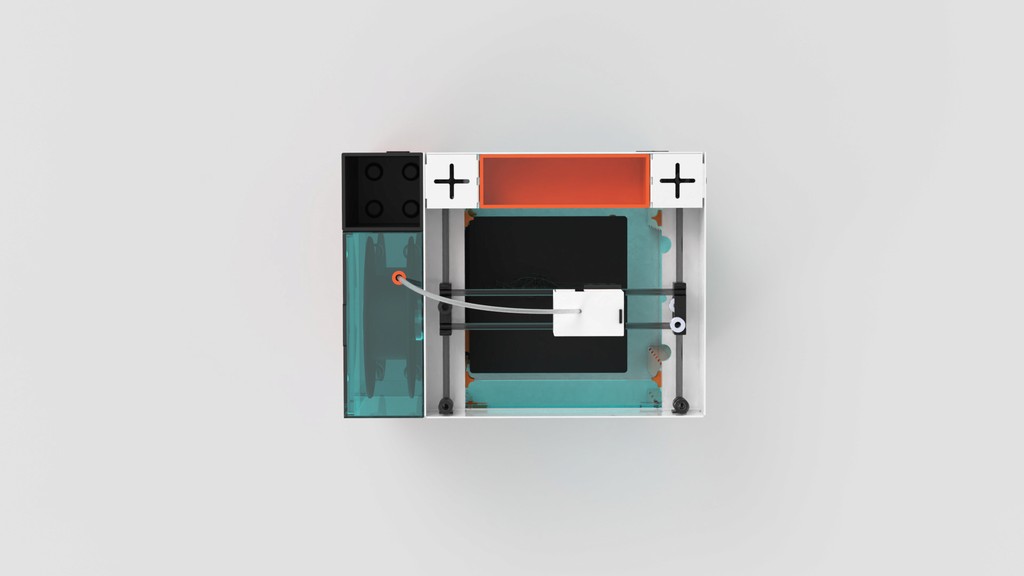

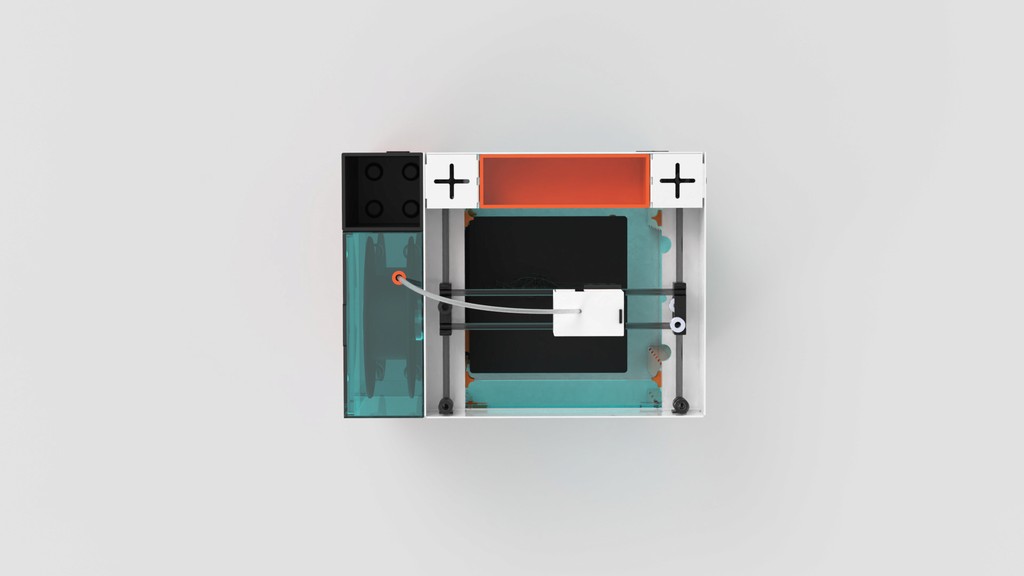

Unlike traditional 3D printer kits, Stack UNO can be assembled in just minutes without the need for mechanical tools, thanks to its Lego-like joineries and knurled screws. Features such as an integrated filament box and USB file transfer make the setup process seamless, allowing beginners to quickly start their 3D printing journey.

Unlike traditional 3D printer kits, Stack UNO can be assembled in just minutes without the need for mechanical tools, thanks to its Lego-like joineries and knurled screws. Features such as an integrated filament box and USB file transfer make the setup process seamless, allowing beginners to quickly start their 3D printing journey.

Process

Process

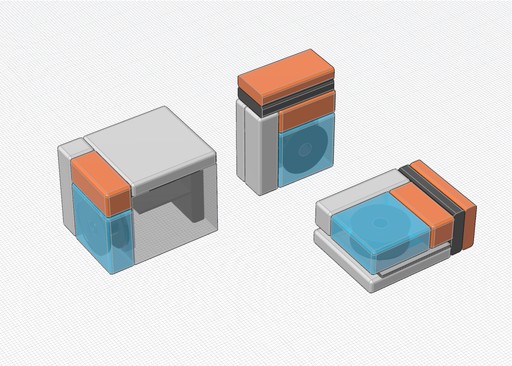

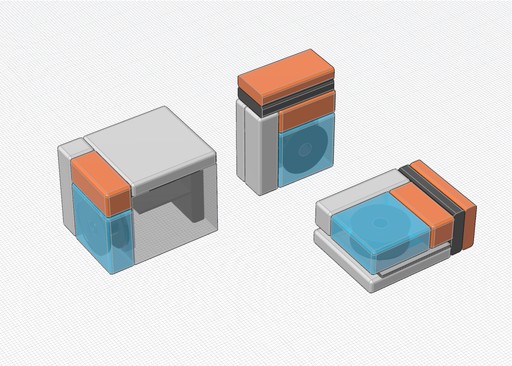

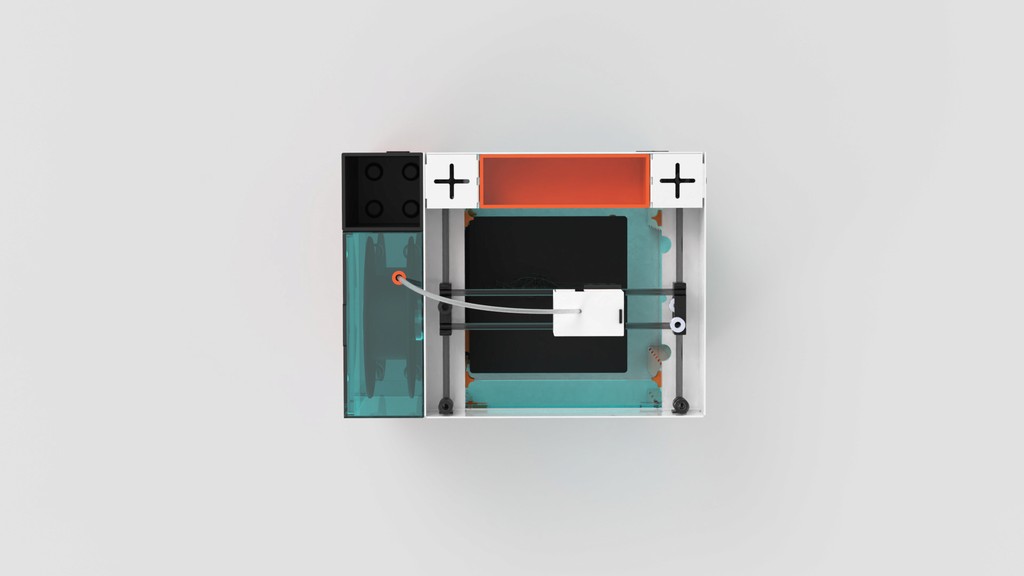

The design strategy was to create something unconventional in this category while maintaining technical precision. Real components were incorporated into the CAD models, and scale mockups were used to test various stacking combinations.

The design strategy was to create something unconventional in this category while maintaining technical precision. Real components were incorporated into the CAD models, and scale mockups were used to test various stacking combinations.

Initial CAD concepts and then tested with scale mockups

Initial CAD concepts and then tested with scale mockups

The snap-fit extruder leverages the printer's gantry system to easily swap heads, enhancing its versatility and expanding its functionality for different CNC tasks.

The snap-fit extruder leverages the printer's gantry system to easily swap heads, enhancing its versatility and expanding its functionality for different CNC tasks.

The core idea behind this project was to make "making" fun. It felt ironic that machines designed for creativity often look intimidating, potentially discouraging people from learning. My approach was to design a machine that inspires, from its appearance to its functionality, encouraging users to take up 3D printing as a hobby. This was also my first technically complex project, which made balancing technical soundness with an approachable design even more important.

The core idea behind this project was to make "making" fun. It felt ironic that machines designed for creativity often look intimidating, potentially discouraging people from learning. My approach was to design a machine that inspires, from its appearance to its functionality, encouraging users to take up 3D printing as a hobby. This was also my first technically complex project, which made balancing technical soundness with an approachable design even more important.

🔗 Design log